EAM DATA SOLUTIONS

Enterprise Asset Management (EAM) refers to the systematic management of an organization’s physical assets throughout their lifecycle. It involves the planning, acquisition, deployment, operation, maintenance, and disposal of assets to maximize their value and optimize their performance.

EAM encompasses a wide range of assets, including machinery, equipment, vehicles, infrastructure, buildings, and technology systems. It is particularly relevant for asset-intensive industries such as manufacturing, energy and utilities, transportation, and facilities management.

Key components of Enterprise Asset Management

➼ Asset Acquisition

➼ Asset Deployment

➼ Asset Operation

➼ Asset Maintenance

➼ Asset Tracking and Inventory

➼ Asset Disposal

Effective EAM implementation can bring several benefits to an organization, including improved asset utilization, reduced maintenance costs, increased operational efficiency, enhanced regulatory compliance, better risk management, and improved overall productivity.

Overall, Enterprise Asset Management helps organizations optimize their asset investments, minimize downtime, and ensure that their physical assets are efficiently managed throughout their lifecycle.

Contact us today to learn more about how our Enterprise Asset Management services can help you optimize your asset performance, reduce downtime, and drive operational efficiency. Let us be your trusted partner in managing your valuable assets.

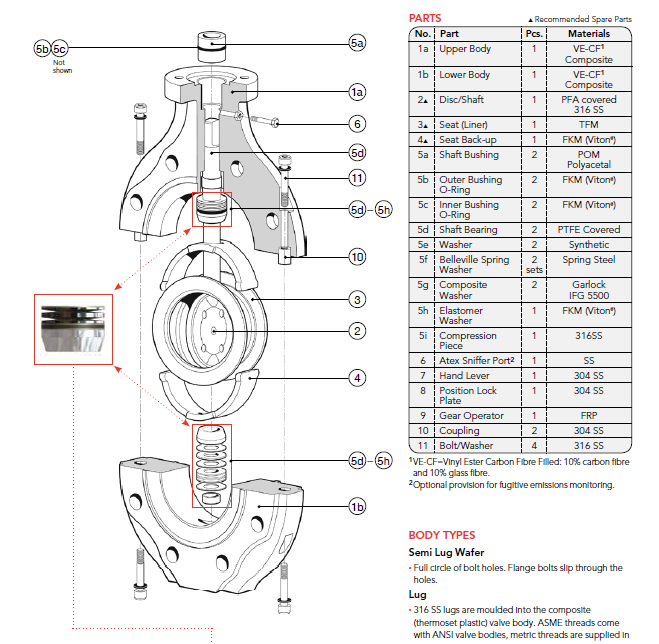

BILL OF MATERIALS

Bill of Materials (BOM) is a comprehensive list of all the components, sub-assemblies, and raw materials required to manufacture a product. It is an essential document in manufacturing and production processes, as it provides a detailed breakdown of the items needed to build a specific product.

Key information includes in BOM

➼ Part Number

➼ Part Name/Description

➼ Quantity

➼ Unit of Measure

➼ Reference Designators

➼ Revision Level

➼ Suppliers

➼ Lead Time

➼ Cost

Benefits of Effective BOM

➼ Enhanced Efficiency

➼ Cost Control

➼ Improved Collaboration

➼ Version Control

➼ Inventory Management

A typical BOM may have multiple levels, starting with the top-level or parent product and then breaking down into sub-assemblies and individual components. Each sub-assembly may have its own BOM, leading to a hierarchical structure.

The BOM serves as a crucial reference for various departments, including engineering, procurement, production, and inventory management. It ensures that all the required components are available in the right quantities at the right time, preventing production delays and helping maintain consistency and quality across products.

At Sanvas, we understand the critical role that a well-structured BOM plays in manufacturing process. With our expertise in various Industry/Manufacturing Sector, we offer tailored solutions to help you streamline your production and achieve better outcomes.

Our Company

- Corporate Profile

- What we do

- Our values

- Contact

Our Services

Contact

- GR Complex, 2nd Floor, Pallikaranai, Chennai - 600100, Tamil Nadu, India

- +91-44-35688119

- +91-44-45564390

- +91-9487401654

- [email protected]